Project Description

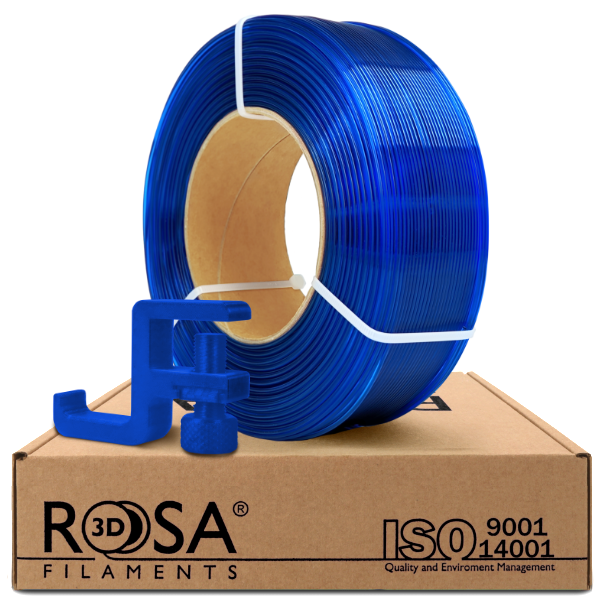

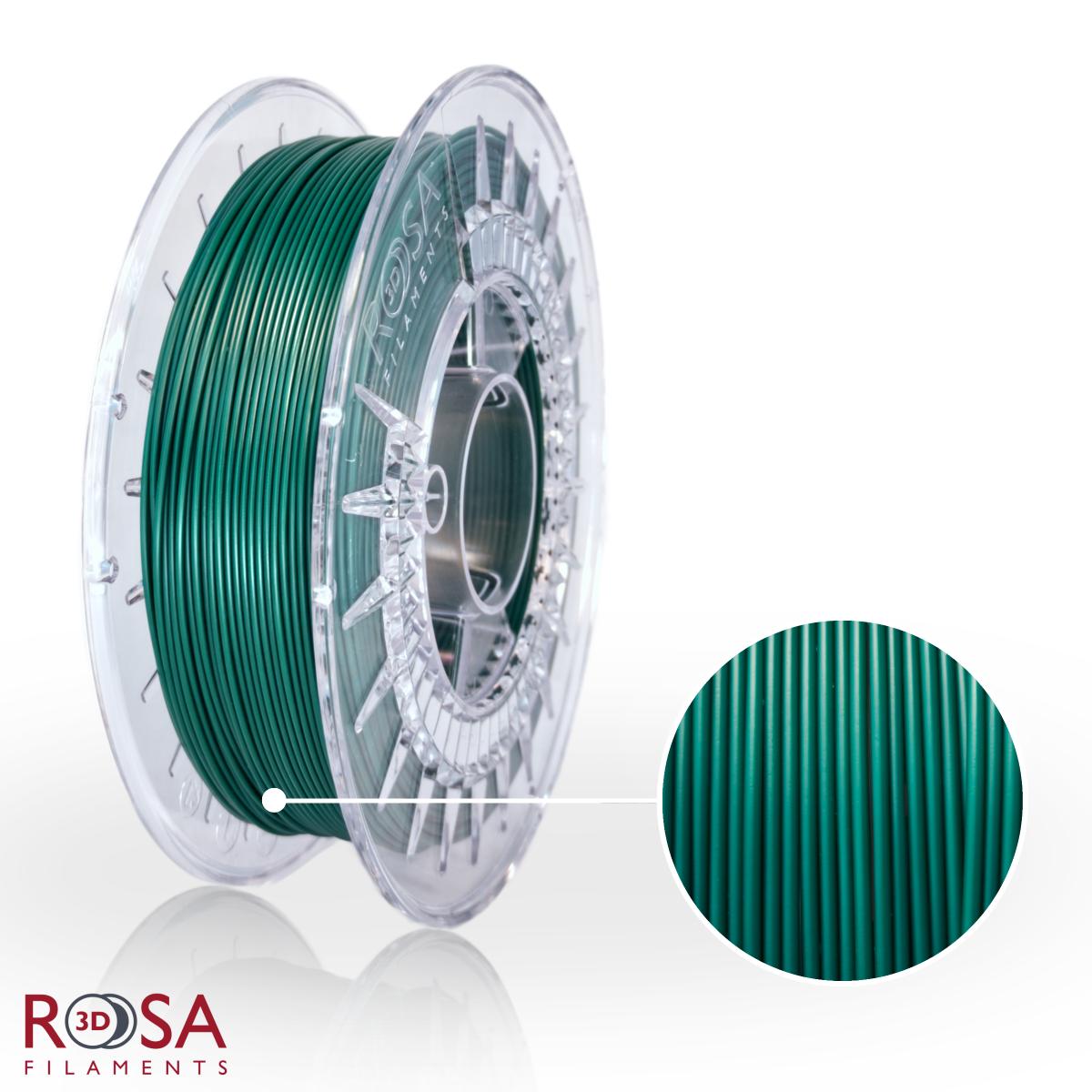

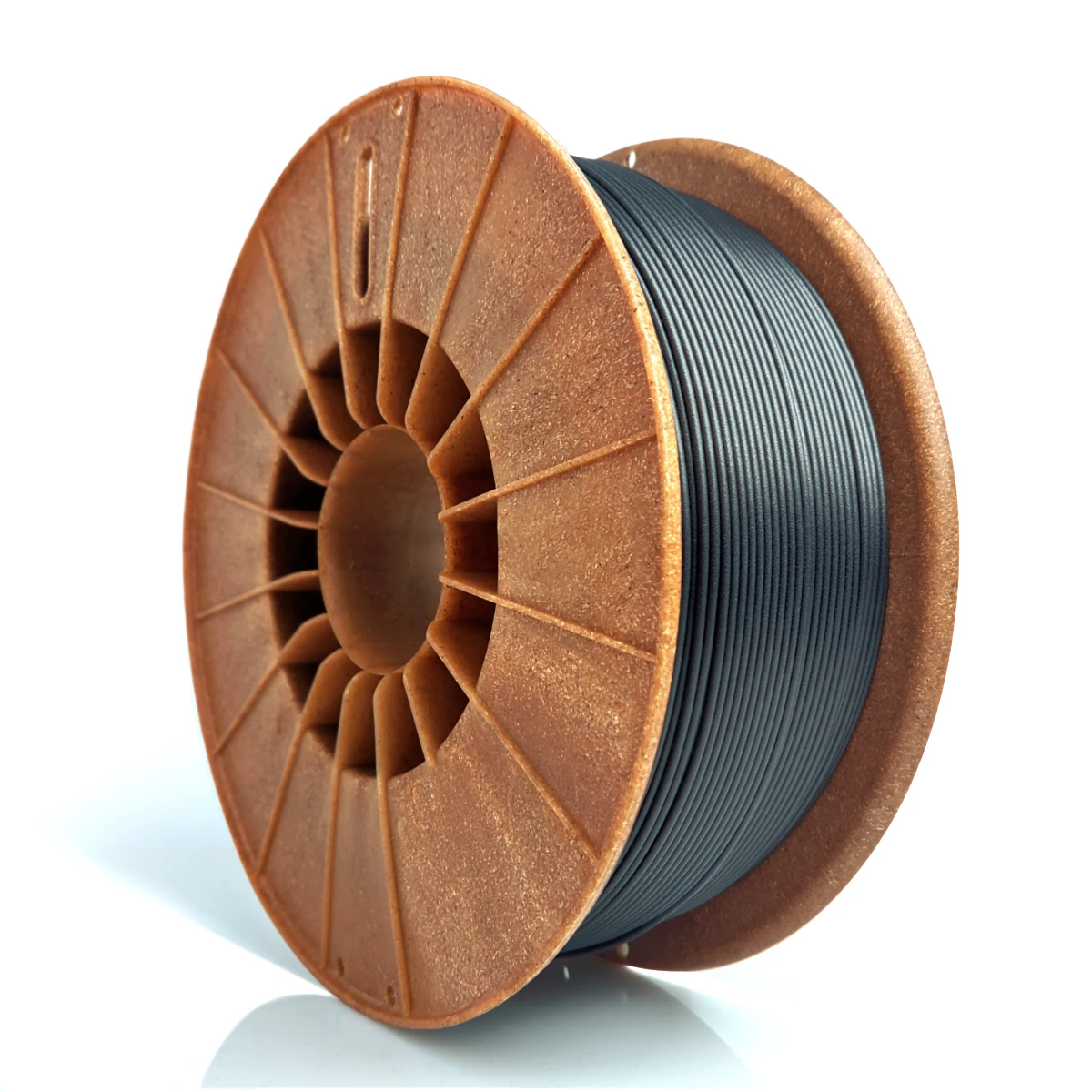

PCTG is an advanced 3D printing filament, belonging to the same polyester family as the popular PET-G. Compared to PET-G, PCTG has higher impact strength, heat resistance (up to 76°C) and transparency. It offers an interesting alternative to PET-G.

Like PET-G, PCTG does not require a heated print chamber, making it an excellent choice if you plan to print on open hobby printers.

PCTG is characterised by high flexibility, strong adhesion between layers, high viscosity and minimal shrinkage. Its characteristics enable easy and efficient printing, even for those without much 3D printing experience.

3D printing using PCTG is widely used in various sectors. In industry, it is an ideal choice for creating parts, small batch production and usable models, confirming the versatility of this material.

The automotive sector also benefits from the advantages of PCTG, using it to print accessories, components in the engine compartment, vehicle component housings, as well as components such as air intakes and fluid inlets (chemical resistance).

In the world of sport, PCTG proves its value in the production of various types of accessories, protectors, etc. The properties of this material guarantee not only the high durability of the finished prints, but also their aesthetics and functionality.

Diameter

Diameter

1.75 mmNet weight

Net weight

1000g (vacuum packed with a moisture absorber)Color

Color

APPLICATION

APPLICATION

- spare parts,

- small batch production,

- utility models,

- engine compartment accessories and components,

- vehicle component housings,

- air intakes,

- service fluid inlets,

- sports accessories, protectors, etc.

HOW TO PRINT

HOW TO PRINT

Recommended printing temperature 240-270°C.

Recommended table temperature: 60-80°C.

Heated table required

TECHNICAL PARAMETERS

| Diameter | 1.75 mm |

| Diameter tolerance | +/- 0.05 mm |

| Oval tolerance | +/- 0.02 mm |

| Net weight | 1000g (vacuum packed with a moisture absorber) |

| Print temperature | 240-270 °C |

| Bed temperature | 60-80 °C |

For more details, such as the standards against which the tests were done, see the technical data sheet of the filament (TDS).

PHYSICAL PARAMETERS

| Density | 1,24 g/cm3 |

| Odor | Odorless |

| Tensile strength (to break) | 46 MPa |

| Notched Izod impact strength | 92 kJ/m2 |

| Vicat softening point | 76/64 °C (0,455 MPa/1,82 Mpa) |

Files to download