As a manufacturer of plastic products, we are aware of the environmental impact of our products. That is why one of our main priorities is environmentally friendly actions, e.g. in the field of packaging. We minimise the negative impact on the environment through a number of production solutions, such as the use of renewable energy sources including the sun, closed water circuits, etc. In the packaging of our products, we ensure that our packaging cartons are simple and environmentally friendly. We have introduced spools made of eco-friendly raw material, and now it is time to minimise the waste left over from the 3D printing process.

NEW SPOOL

This new spool, created as a sign of our commitment to the environment, aims to minimise the amount of waste generated in the 3D printing process.

It is built from a cardboard core with two Masterspool ROSA3D’ reusable discs pressed onto it. These discs are injection-molded for enhanced durability and precision, using R-PC, a 100% recycled polycarbonate material.

Thanks to the folding spool, minimal waste is generated post-printing, amounting to a lightweight 30g cardboard core that can easily be disposed of in a paper bin.

The spool features standard dimensions, aligning with those commonly found in the market: outer diameter of 201.7mm, hole diameter of 52mm, width of 65mm, disc weight of 220g, cardboard coil weight of 30g, and a total spool weight of 250g.

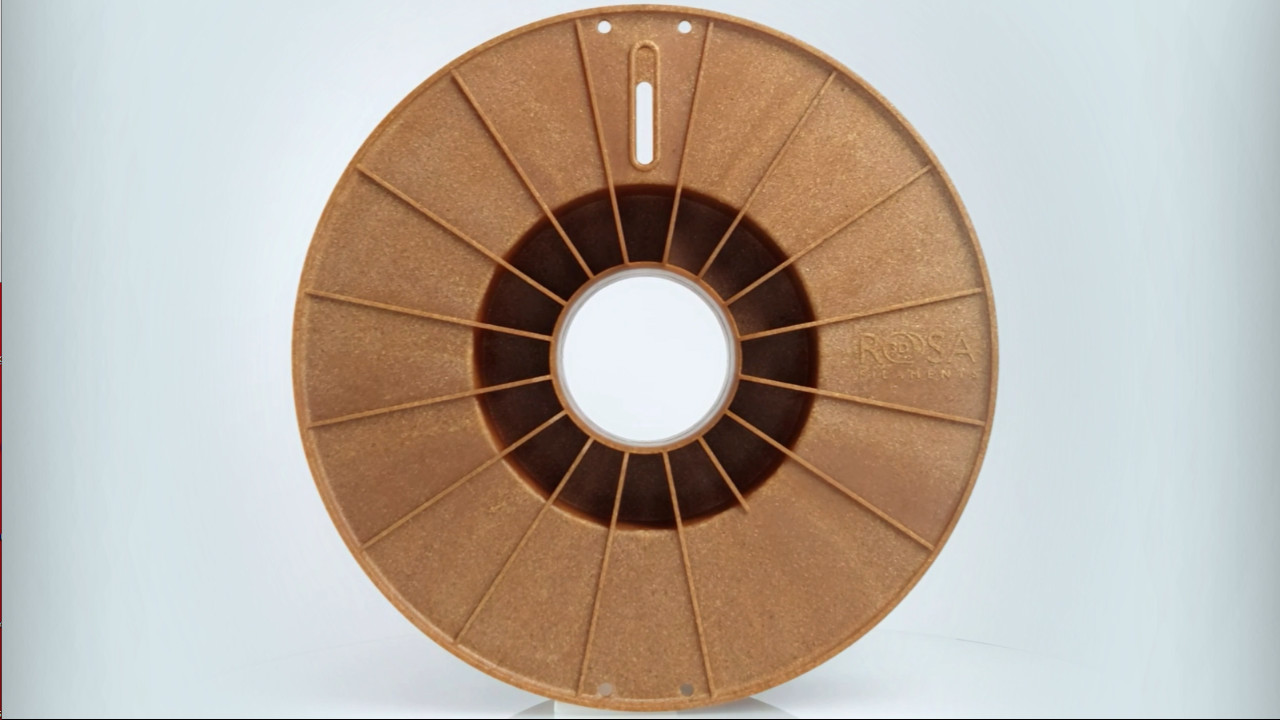

WOODEN SPOOL

The spool is made of recycled polypropylene mixed with over 30% wood dust, which gives it its brownish-sandy colour. The use of natural filler allowed us to reduce the amount of plastic used in the spool.

Thanks to the materials used and the thoughtful design our spool is almost 20% lighter than standard polycarbonate spools (200 grams vs 256 grams).

The dimensions are the same as for most spools on the market (200mm diameter, 52mm hole, 55mm thickness).

ECO-SOLUTIONS

Our Masterspool ROSA3D discs are made using recycled polycarbonate (R-PC), making them strong and eco-friendly. The cardboard coil is also environmentally friendly, crafted from natural materials. Our spool is specially designed so you can reuse the discs with our ReFills. After you finish printing, the discs can be used again, and the cardboard part can easily be recycled. Just throw it in the paper bin. This design not only reduces waste but also lessens our environmental impact. Plus, these Masterspool ROSA3D discs are not only durable but also have a modern look

Our wooden spool, on the other hand, is constructed from recycled PP and wood fibres. The production of original polypropylene generates almost two times smaller carbon footprint (approx. 1.6 kg for PP) than the polycarbonate most commonly used in spools (approx. 4.1 kg for PC). In addition, we reduce the amount of CO2 emitted into the atmosphere by using recycled PP material in our spool. But these aren’t all the factors that reduce the amount of greenhouse gases generated during the production of the spool. The overall carbon footprint is further reduced by the use of wood fibres as a filler. More CO2 is absorbed by a tree during its lifetime than is produced during its processing. This results in the most environmentally friendly plastic spool available on the market with the final emission factor of ~0.3 kg.

REDUCTION IN CO2 EMISSION

TRANSPARENT PC SPOOL

OUR SPOOL

OUR SPOOL

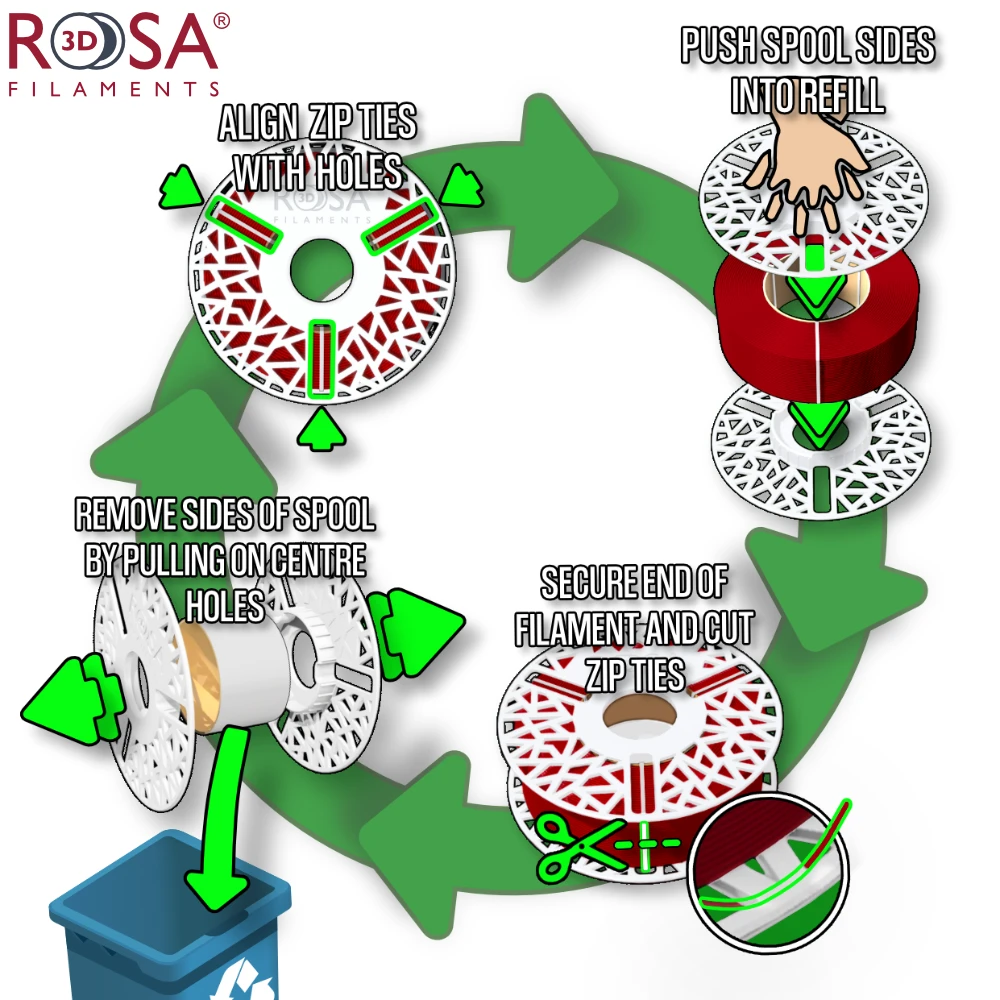

RE-USE

The Masterspool ROSA3D discs that are part of our new spool can be reused for ReFill from our range. Just press them onto the cardboard coil, secure the end of the filament from unwinding and then remove the zip ties.