Project Description

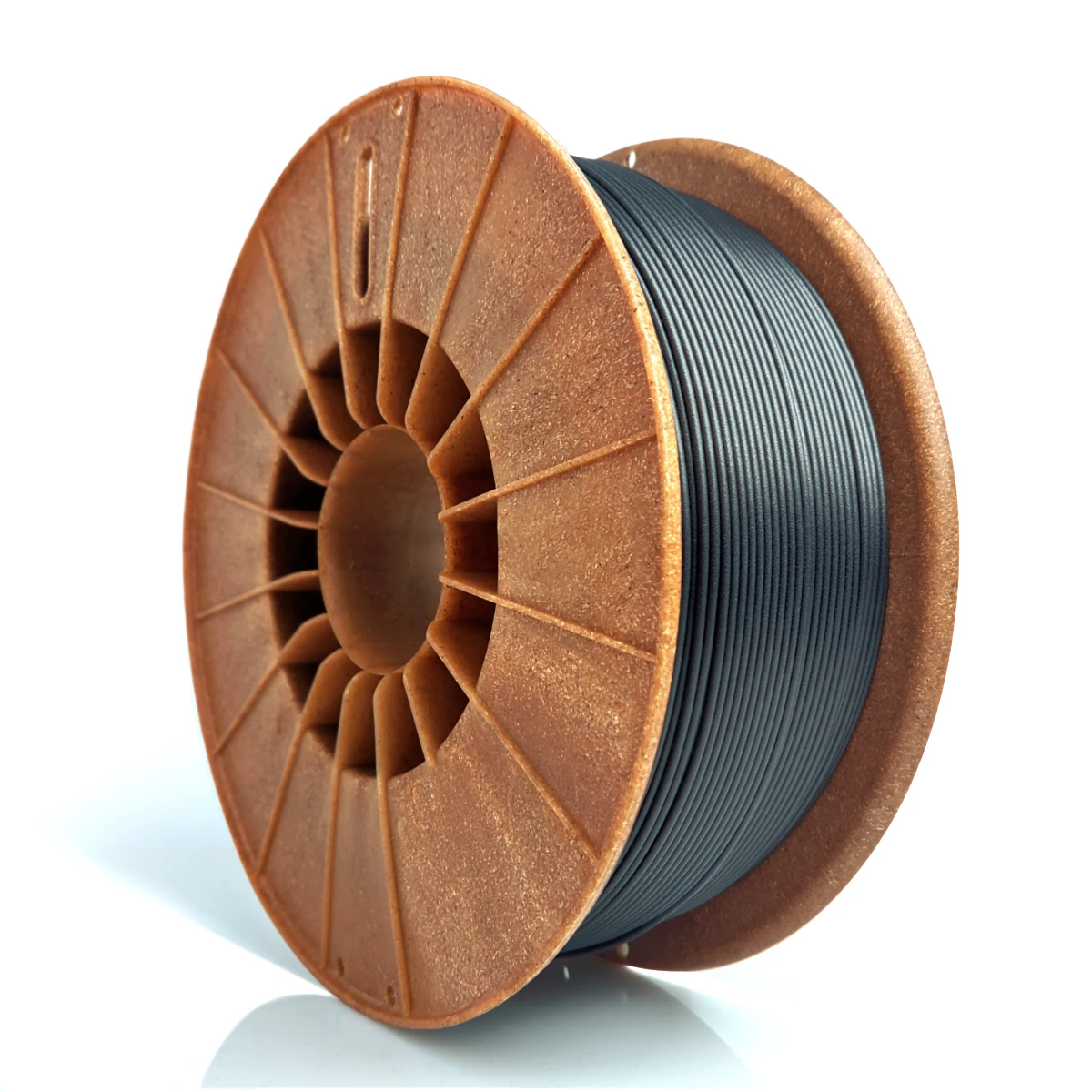

PA12+CF15 it combines the advantages of nylon and carbon fibers, resulting in an extraordinarily durable product.

Printouts made of PA12+CF15 filament have a thermal resistance of 160°C. They have been successfully powder coated and polymerized in an oven at 181°C for 15 minutes.

PA12+CF15 prints can be used as a replacement for steel elements to reduce the weight of the device or structure without losing the strength of the entire system.

The PA12+CF15 filament is easy to print and, thanks to the carbon fiber addition, has low processing shrinkage. Recommended especially for professionals and advanced users. When printing PA12+CF15, hardened steel nozzles are recommended (brass and aluminum nozzles are subject to abrasion), suggested nozzle size > 0.4 mm.

For detailed technical data of the product, please refer to the technical sheet ("files to download").

Diameter

Diameter

1.75 mmNet weight

Net weight

500 g; 1000 g; 2500 g (vacuum packed with desiccant)Color

Color

APPLICATION

APPLICATION

drone parts

prototyping

automotive industry

replacements of steel elements

parts intended for powder coating

extremely durable mechanical parts

HOW TO PRINT

HOW TO PRINT

Recommended printing temperature: 250-300 °C.

Recommended table temperature: 70-120 °C.

When printing with PA12+CF15, hardened steel nozzles are recommended (brass and aluminum nozzles are subject to abrasion), suggested nozzle size >0.4 mm. We also recommend installing a full-metal heatbreak (no PTFE tube inside) due to the high extrusion temperature. If there are first layer adhesion problems adhesion, an adhesive spray should be used.

TECHNICAL PARAMETERS

| Diameter | 1.75 mm |

| Diameter tolerance | +/- 0,05 |

| Oval tolerance | +/- 0,02 |

| Net weight | 500 g; 1000 g; 2500 g (vacuum packed with desiccant) |

| Print temperature | 250-300 °C |

| Bed temperature | 70-120 °C |

The test standards can be found in the filament technical data sheet (TDS).

PHYSICAL PARAMETERS

| Density | 1.07 g/cm3 |

| Odor | Odorless |

| Tensile elongation | 5 % |

| Tensile strength (to break) | 125 MPa |

| Tensile modulus | 8000 MPa |

| Thermal deformation temperature | 170°C (0,45 MPa), 150°C (1,8 MPa) |

| Charpy impact strength | unnotched, 23°C: 75,0 kJ/m2; notched, 23°C: 15,0 kJ/m2 |