Project Description

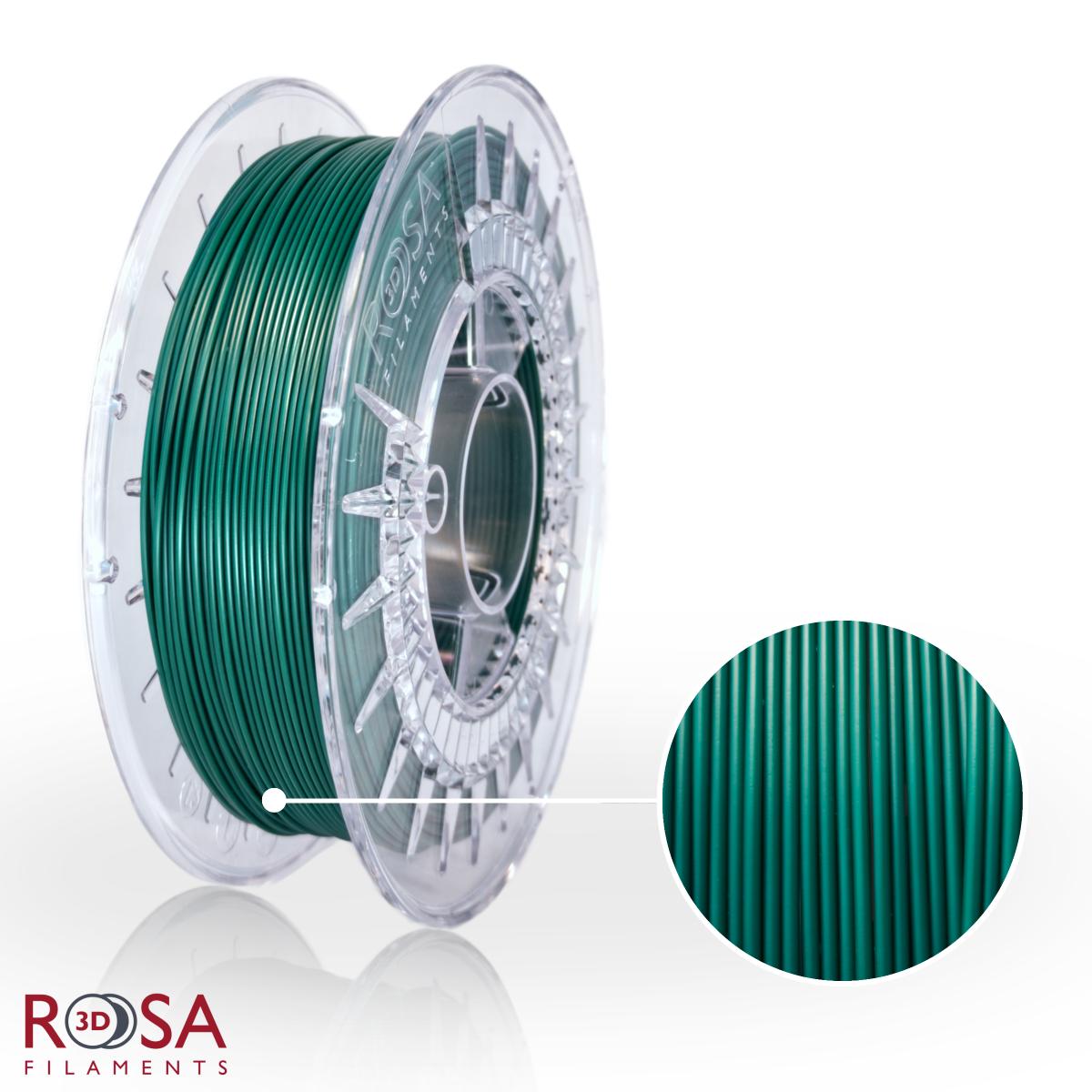

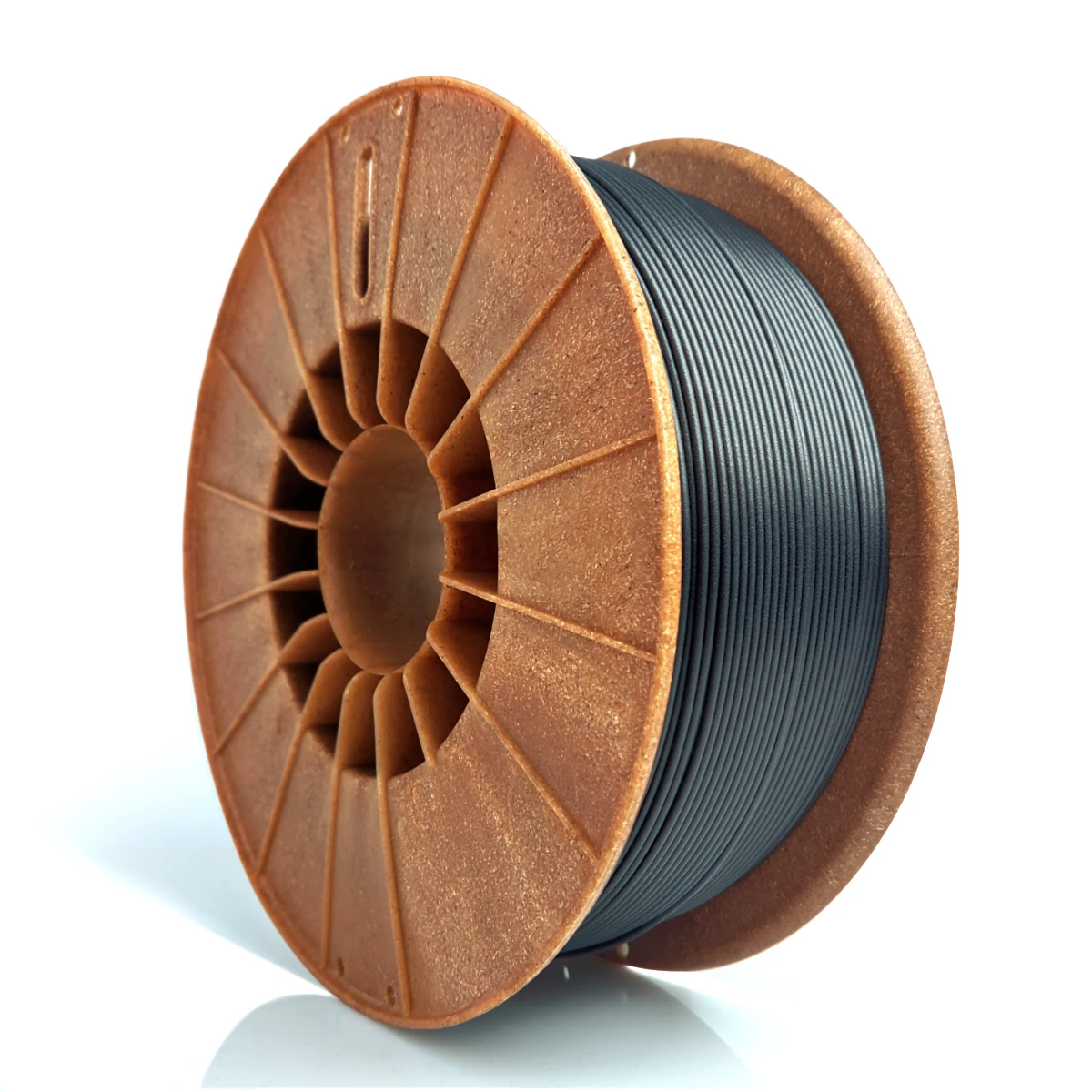

ASA filament (acrylonitrile-styrene-acrylic) by ROSA3D is a UV resistant, moisture resistant and heat resistant polymer. ASA’s UV resistance makes it an ideal material for outdoor applications, that are going to be exposed intensively to the sun and various weather conditions.

ASA is suitable when you need an efficient material, which is going to cause less printing problems than ABS. The filament has lower shrinkage level, and the produced odor is much less perceptible. The softening point for ASA printouts is higher compared to PLA and PETG, there are no signs of deformation up to temperatures close to 94 ° C. The exceptional mechanical and thermal properties of ASA as well as excellent resistance to UV radiation make it an perfect material and an ABS alternative for use in the automotive and marine industries and for outdoor applications such as mirror housings, covers, radiator covers and sensor housings.

Diameter

Diameter

1.75 mmNet weight

Net weight

700g; 900 g; (vacuum packed with a moisture absorber)Color

Color

APPLICATION

APPLICATION

Housings / shades, machine parts.

HOW TO PRINT

HOW TO PRINT

Recommended printing temperature 230 - 260 ° C.

Recommended bed temperature: 70-110 °C.

TECHNICAL PARAMETERS

| Diameter | 1.75 mm |

| Diameter tolerance | +/- 0.05 mm |

| Oval tolerance | +/- 0.02 mm |

| Net weight | 700g; 900 g; (vacuum packed with a moisture absorber) |

| Print temperature | 230-260 °C |

| Bed temperature | 70-110 °C |

The test standards can be found in the filament technical data sheet (TDS).

PHYSICAL PARAMETERS

| Density | 1,07 g/cm3 |

| Odor | Almost odorless |

| Tensile elongation | 35 % |

| Tensile strength (to break) | 40 MPa |

| Tensile modulus | 1750 MPa |

| Notched Izod impact strength | 45 kg*cm/cm |

| Vicat softening point | 94 °C |

Files to download