Project Description

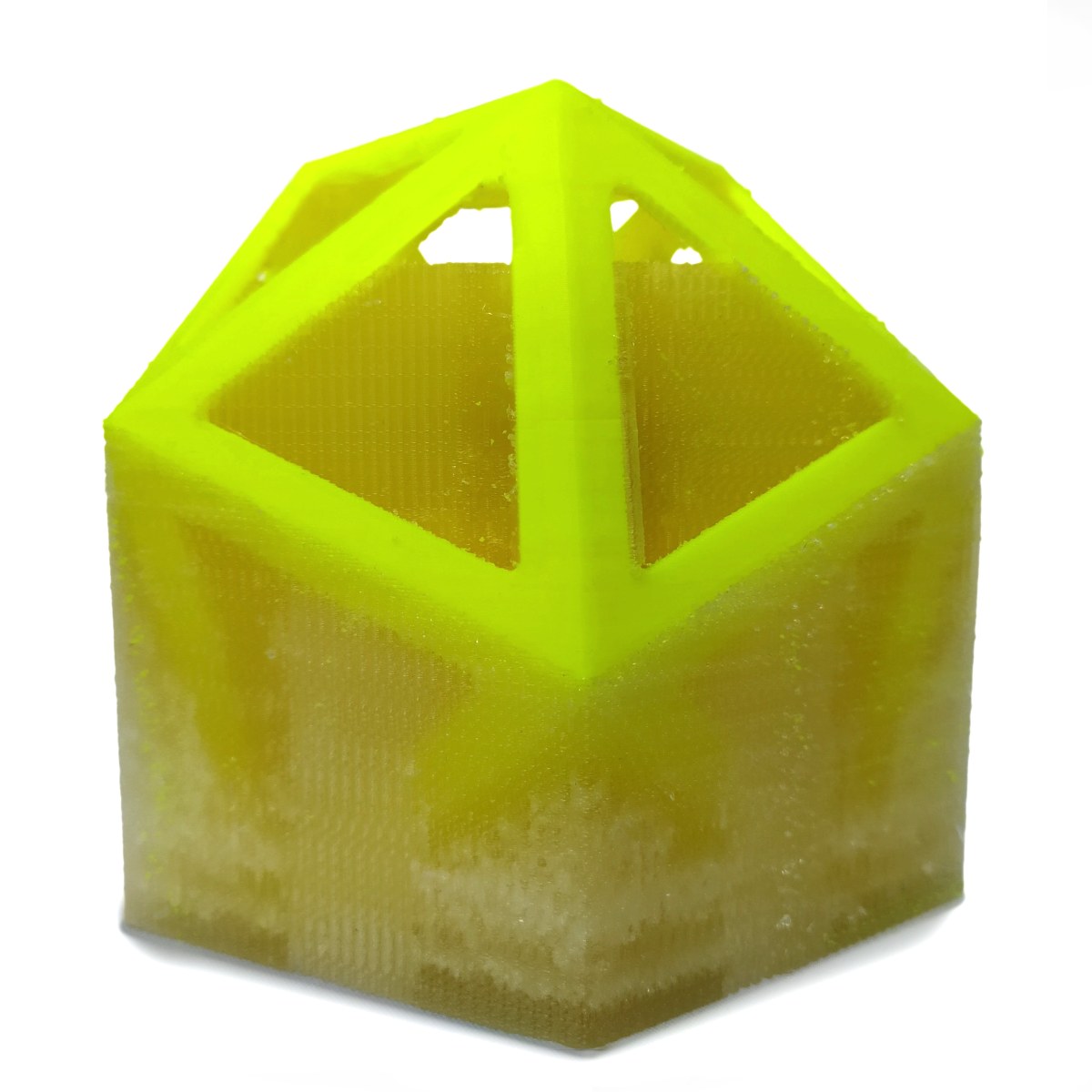

PVA filament, or polyvinyl alcohol, is a water-soluble thermoplastic. Therefore, it is made to be a support material. Complex prints made of other materials (eg PLA, PET-G, TPU, PA) can be printed with the help of PVA support structures.

On a multi-extruder printer, you can print models that would otherwise require printing in parts, gluing or would not be possible at all! After printing, just immerse the model in warm water (but not too hot, keep the thermal deformation temperature of the actual part in mind). Depending on the dimensions of the model and the amount of PVA used, such a bath may take from several minutes to several hours. Mixing the water in the tank can speed up the dissolution process.

The improved version - PVA-2 - has a higher temperature resistance making it ideal as a support material when printing from technical application materials. The PVA-2 filament can be used in an actively heated chamber at a maximum temperature of 70°C.

PVA can be printed at low temperatures, in an open printer and on an unheated bed. Due to its hygroscopicity, the filament must be stored in a tightly closed bag or container with a moisture absorber. Storing PVA away from sunlight and at a temperature between 15°C and 25°C will extend its shelf life.

Diameter

Diameter

1,75 mmNet weight

Net weight

500 gColor

Color

APPLICATION

APPLICATION

Supports:

- easy to remove, because they are water-soluble,

- in places where supports made of insoluble materials would be impossible to remove,

- leaving a smooth print surface after removal,

- biodegradable.

3D prints:

- in any orientation on the worktable to improve the aesthetics and/or strength of the element,

- suspended in the air,

- supported by a structure made of PVA.

HOW TO PRINT

HOW TO PRINT

recommended printing temperature: 190-215°C

recommended table temperature: 50-70°C

The filament can be printed on unheated tables. In case of problems with adhesion, we recommend the use of an adhesive agent.

Cooling the printout is recommended. Its power should be adjusted to the capabilities of the printer and the geometry of the printed model.

TECHNICAL PARAMETERS

| Diameter | 1,75 mm |

| Diameter tolerance | +/- 0.05 mm |

| Oval tolerance | +/- 0.02 mm |

| Net weight | 500 g |

| Print temperature | 190-215°C |

| Bed temperature | 50-70°C |

The test standards can be found in the filament technical data sheet (TDS).

PHYSICAL PARAMETERS

| Density | 1.25 g/cm3 |

| Odor | odorless |

| Thermal deformation temperature | 41.5°C (HDT A, according to ISO 75) |

| Vicat softening point | 60.2°C |