Have you always dreamed of 3D printing with wood? Are you way past testing not-so-wooden filaments? Has their price-quality ratio disappointed you? Maybe you’re striving to produce less waste but using a 3D printer takes you away from your goal? Do you want the filament you use to not be such a burden to the planet?

In our offer you will find BioWOOD filament – compostable even in a home composter. What’s more, the addition of real wood fibers makes you feel the pleasant smell of wood right after unpacking the spool. And for post-processing the printout, you can use the same methods that work well for wood. The filament is sold at 500g net.

TABLE OF CONTENTS

What is BioWOOD from ROSA3D made of?

Biowood is a composite material. The main components of wooden filament are: polycaprolactone (PCL), polyester, starch, lignin, natural resins, waxes and oils, natural fatty acids, cellulose and natural fibers.

The filament and the print, have a wooden scent and can be processed mechanically thanks to the addition of wood fibers. Thanks to the binding particles and resins it is possible to produce a material in the form of a thread (with a diameter of 1.75 mm in our case), and then wind it on a spool.

Printouts made of BioWOOD material resemble natural wood with its structure. Thanks to their porous structure, they absorb the paint perfectly. They can also be successfully stained, sanded and glued.

3D Benchy printed from BioWOOD filament and then stained

Wooden barrel printed from BioWOOD and then painted

As you could probably guess, the material is not fireproof.

The raw material from which BioWOOD filament is made, complies with European regulations:

- Regulation (EC) No. 1935/2004 of the European Parliament and of the Council of 27 October 2004;

- Commission Regulation (EU) No 10/2011 of 14 January 2011.

The above documents regulate whether the raw material may be approved for contact with food. However, in the case of products that come into contact with food, it is the manufacturer of the final product that has to carry out product-specific certification.

How to print with BioWOOD?

Printing parameters

| Printing temperature [degrees Celsius] | 170-200 |

| Bed temperature [degrees Celsius] | 40-50 |

| Print speed [mm/s] | 60-80 |

| Retraction amount [mm] | 1-4 |

| Retraction speed [mm/s] | 45 |

| Fan [%] | 50-100 |

| Compatible bed surfaces | alluminum, glass, PEI, PC (polycarbonate) |

* changing the extrusion temperature affects the shade of the printout

**printing bed does not require heating

What is the nozzle temperature for printing BioWOOD?

The extrusion temperature should not be too high, as this can burn the filament and/or clog the nozzle. What’s more, by changing the printing temperature, you can control the color of individual print parts. For a brass nozzle we recommend 170-200oC.

Speaking of the nozzle temperature, we must mention the extrusion speed. The faster we print, the higher the temperature we need. Why? To keep the pressure value at a level that is just right for the extruded material. In our tests, we didn’t have any issues printing at speeds of 60-80 mm/s.

What nozzle to use for BioWOOD?

Due to the size of the fibers – we suggest using a nozzle with a hole diameter greater than or equal to 0.4 [mm]. A brass nozzle should have no problems with continuous printing of this material. As for the heatbreak, it is possible to print both with a Teflon tube connector and a full-metal connector.

Of course, the optimal printing temperature will be influenced by the material from which both the nozzle and the heatbreak are made.

Printing with BioWOOD using a Bowden extruder is possible. However, be aware that the material is stiff and brittle. Rapid movements of the head or too acute of a bending angle of the filament entering the hotend may result in a broken thread.

Bowl and cup printed with BioWOOD

The material can be printed with open frame 3D printers. Although enclosure affects the layer to layer adhesion positively. It also helps to stabilize the temperature inside the printer. What’s more, it prevents blasts of cool air, which may cause print shrinkage with materials sensitive to temperature changes. Shrinkage can lead to premature, uncontrolled detachment of the printout from the heatbed. You need to remember that there are filaments (e.g. ASA) that soften due to too high temperature inside the device. Softening may result in issues with feeding the filament and eventually to a clogged nozzle.

On which bed should you print a wooden filament?

The material can be printed on various surfaces without the need for heating: both on a glass bed, a PC sheet, on a PEI board and on an aluminum plate. For PEI, we recommend using a thin layer of adhesive so that you can tear off the printout without damaging the table. Of course, you should always make sure that the distance between the nozzle and the bed is adjusted to the height of the layer. Depending on the print to bed contact area and the print geometry (which is affected by the density and type of infill, the number of walls, top and bottom layers, supports etc.), different stresses occur, and therefore – problems with print to bed adhesion. To improve adhesion, you can raise the temperature of the table or use standard solutions such as: painter’s tape, adhesive spray, glue stick, etc.

Figurine made of BioWOOD filament – author of photos and prints: Sebastian Pontus

Do not rush to remove the printout from the table. Only complete cooling will stiffen the model and prevent it from being deformed by your grasp. It is safe to remove the printout from the heatbed when the temperature of the heating plate drops to room temperature.

Does BioWOOD cause problems with stringing?

The material is characterized by a relatively high flow, higher than PLA Starter, therefore, with some models, threading is unavoidable. To minimize stringing, it will be necessary to find the optimal retraction parameters (different depending on whether the printer has Bowden or Direct feeding). Try to trace what non-printing movements the printer performs in a given program, adjust the appropriate temperature and speed of printing. Luckily, the threads can be removed quickly and easily without leaving any traces on the printout. This can be done with your hand, with a knife blade or with sandpaper.

Chess set made of BioWOOD filament – author of photos and prints: Sebastian Pontus

Application

In this field, sky is the limit! Here are some suggestions for using BioWOOD from us:

– musical instruments (for example violin – listen and see them play on our Facebook page!),

– dishes,

– furniture,

– toys/pendants,

– ornaments.

Violin made of BioWOOD filament

Owls made of BioWOOD filament – author of photos and prints: Jakub Rosły

Technical parameters

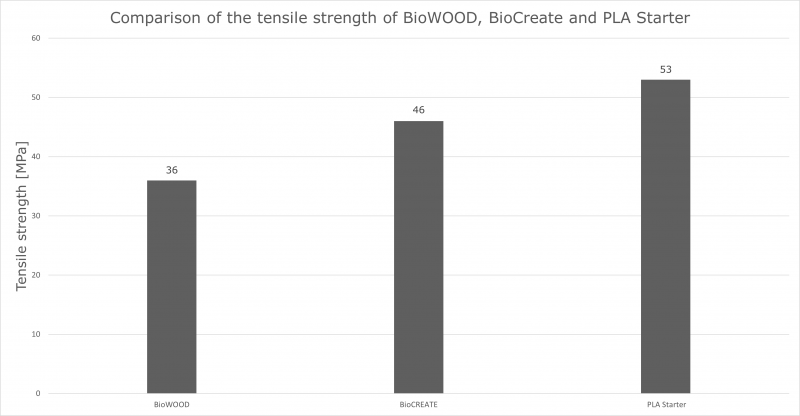

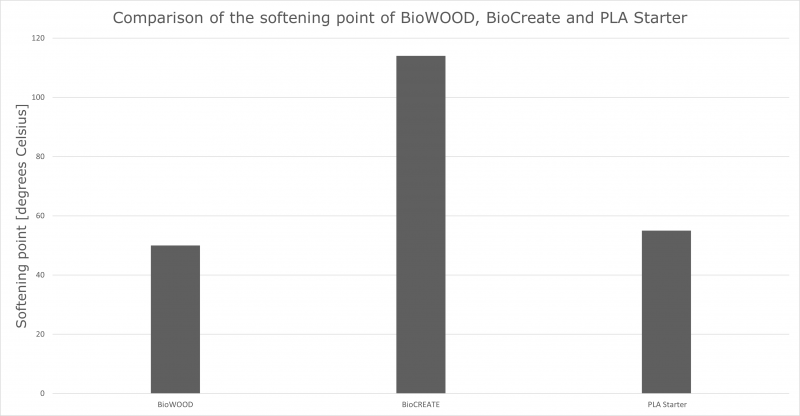

BioWOOD has the lowest softening point of all filaments currently available in our offer. It is closest to PLA Starter, which has an HDT of 55°C.

Physical properties

| Softening point [degrees Celsius] | 50 |

| Density [kg/m^3] | 1260 |

| Elastic modulus [MPa] | 3200 |

| Tensile strength [MPa] | 36 |

If you want to learn more about technical parameters of the BioWOOD filament, download technical data sheet (TDS) from the product page.