Have you dreamed of creating 3D prints with a surface as smooth as a sheet of glass? Or are you looking for a filament that is easy to post-process and allows you to achieve a unique look for your works? Whether you’re an experienced 3D printer user or starting out, we’ve got some tips for you that we hope will make using PVB filament easier.

In this article, you will learn about the unique properties of PVB filament, which, thanks to its ease of processing with isopropyl alcohol (IPA), is an interesting proposition for hobbyist 3D printer users. You’ll find advice on PVB printing and post-processing, tips on maintaining the quality of the filament, and inspiration for using this material in your future projects. Read below to find out more.

TABLE OF CONTENTS

PVB filament – Polyvinyl butyral

Polyvinyl butyral (PVB) is a thermoplastic polymer commonly used, among other things, as a film between two layers of glass in car windows. In the world of 3D printing, PVB material, has gained appreciation due to its ability to be easily processed with isopropyl alcohol allowing for smooth 3D prints.

PVB has an ease of printing comparable to PLA. It will be particularly appreciated by 3D printer users looking for an aesthetic experience, for whom the priority is to obtain a smooth surface of the model or the possibility of creating highly transparent 3D prints.

The temperature resistance of PVB is also like PLA – the material starts to deform at about 60⁰C, but already at 55⁰C its surface becomes sticky.

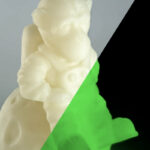

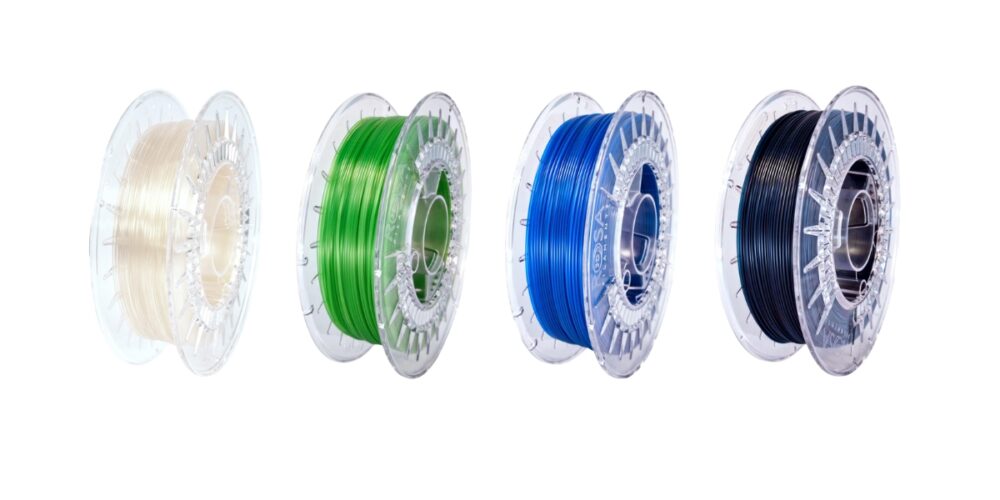

ROSA3D Filaments offers two versions of PVB: transparent and opaque colours. The transparent materials include: PVB Natural, PVB Smooth Blue Transparent and PVB Smooth Green Transparent. These will be ideal for creating transparent models printed in vase mode.

Less transparent materials include PVB Navy Smooth, and fully opaque colours include: PVB Smooth Black, PVB Smooth Red, PVB Smooth Turquoise and PVB Smooth Yellow.

You can find the material’s technical data sheet here.

Would you like to try out our PVB filaments? Check out >> map of our distributors! <<

Filament 3D PVB Natural, PVB Smooth Green Transparent, PVB Smooth Blue Transparent, PVB Navy Smooth .

PVB printing parameters

PLEASE NOTICE! PVB is a highly hygroscopic material. Therefore, it intensively absorbs moisture from its surroundings. If you want successful prints, remember to always dry your filament at approx. 45 ⁰C for 4 – 8 hours before each print.

NOTE: Set a minimum temperature of 45 ⁰C on the filament dryer, and if you are drying the material in the oven, first heat up and stabilise the temperature and then insert the filament spool. If the temperature exceeds 55⁰C because of hysteresis, the external filament wound on the spool may stick together.

Always put the spool back in the bag with the moisture absorber. This will ensure a trouble-free and successful printing.

Recommended printing parameters:

Printing parameters

| Printing temperature [degrees Celsius] | 200-225 |

| Bed temperature [degrees Celsius] | 65-75 |

| Print speed [mm/s] | 60-80 |

| Retraction amount [mm] | Bowden: 2-4; Direct: 0,5-2 |

| Retraction speed [mm/s] | Bowden: 40-70 ; Direct: 30-45 |

| Fan [%] | 50 – 100 |

| Compatible bed surfaces | smooth PEI sheet, satin sheet |

PVB has excellent adhesion to smooth PEI sheet and satin sheet. We do not recommend printing on textured sheet– it can cause adhesion problems for the printed model.

Smoothing with IPA

An unquestionable advantage of PVB is that it can be easily chemically treated with isopropyl alcohol (IPA). This is an excellent way to achieve a smooth and professional surface finish of your 3D prints. The process involves applying IPA to the surface of the print, the effect is a melting of the outer layer and the creation of a smooth surface.

3D printed model with PVB Smooth Red after smoothing process

What is IPA (isopropyl alcohol)? It is a common cleaning, degreasing, and disinfecting product used in the automotive, electronics and optical industries.

There are several ways to smooth the surface of a PVB print using IPA:

Method 1: Polishing in IPA fumes (using a simple polishing chamber or Polymaker Polysher smoothing station)

Using a professional print smoothing station is the fastest and most effective method. However, you can successfully build a simple smoothing chamber yourself.

3D print with PVB Smooth Black before and after smoothing with isopropyl alcohol.

Soak sheets of paper towel in IPA and line a glass container or jar with it. Then place the PVB print inside. The smoothing time depends on the component and the degree of smoothing that you want to achieve.

<iframe title=”YouTube video player” src=”https://www.youtube.com/embed/6PtfhFdByzU” width=”560″ height=”315″ frameborder=”0″ allowfullscreen=”allowfullscreen”></iframe>

Method 2: Direct application of IPA using a fabric cloth, brush, or spray.

Apply a small amount of isopropanol to the surface of the print. If you use a brush or a fabric cloth, take care not to leave fibres on the print surface, which becomes sticky when exposed to IPA.

Method 3: Dipping the print in IPA

Pour the IPA into a container and then immerse your print in it for 15-30 minutes or less (immersion time depends on the solid of the print). Remember!: Too long exposure can lead to excessive softening and deformation of the model.

NOTE: IPA dissolves the outer layer of the print. Whatever method you choose, you will get a better result by treating the print several times over a shorter period of time, allowing the print to dry between processes rather than exposing it to the solvent once but for a long time.

CAUTION: IPA is flammable, so always carry out these processes in a well-ventilated area and away from open fire. It can be irritating to the skin and eyes, so always wear personal protective equipment.

How to achieve models with a transparent surface?

PVB filament will allow you to create models whose walls look like glass or a sheet of ice. If transparency of print’s walls is your priority print your model in vase mode with one outline. For models with more outlines, the layers will still be visible even after smoothing with IPA. You must remember that PVB filament will soften under the influence of IPA. Your print may deform if its walls are too thin. To avoid such a problem, think about choosing a nozzle with a larger diameter (even up to 0.8 mm).

Vase printed with PVB Green Transparent after smoothing with IPA.

Application

PVB filament will enable you to create many interesting projects requiring an aesthetically pleasing surface finish. It is best for printing transparent models, such as jewellery, vases, lamp shades, as well as creating figurines with smooth, glossy surfaces.

Exploring new materials such as PVB filament is one of the many pleasures of the 3D printing world. Its unique aesthetic properties and ease of post-processing make it an attractive choice for many projects. Perhaps it will be the ideal choice for your next idea? You can buy PVB filament from our authorised distributors – find your local distributor.

Do you have any questions? Need help choosing the right filament? We will be happy to help you! We look forward to hearing from you.

Go to >> the map of our distributors << , choose the distributor near you and start creating today!