Project Description

ABS+ material is a widely applicable engineering plastic with moderate shrinkage (0.4-0.7%).

Excellent processing properties such as good flow, bright, vivid colours and very good layer adhesion allow a wide range of applications for this filament.

ABS+ has a high impact strength and is impact resistant.

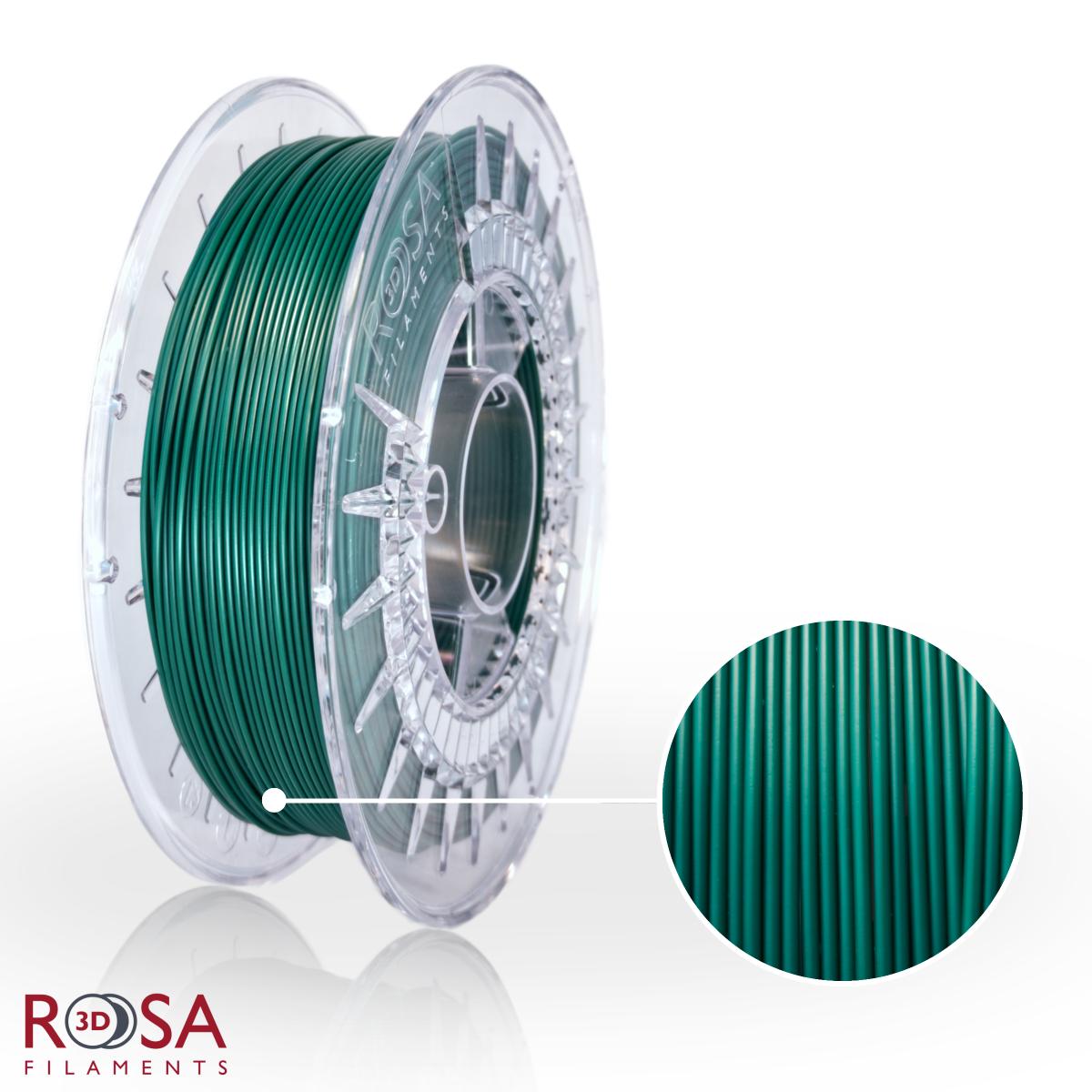

ABS+ from ROSA3D gives an elegant semi-matte finish to the surface of prints. It can be smoothed with acetone.

Diameter

Diameter

1.75 mmNet weight

Net weight

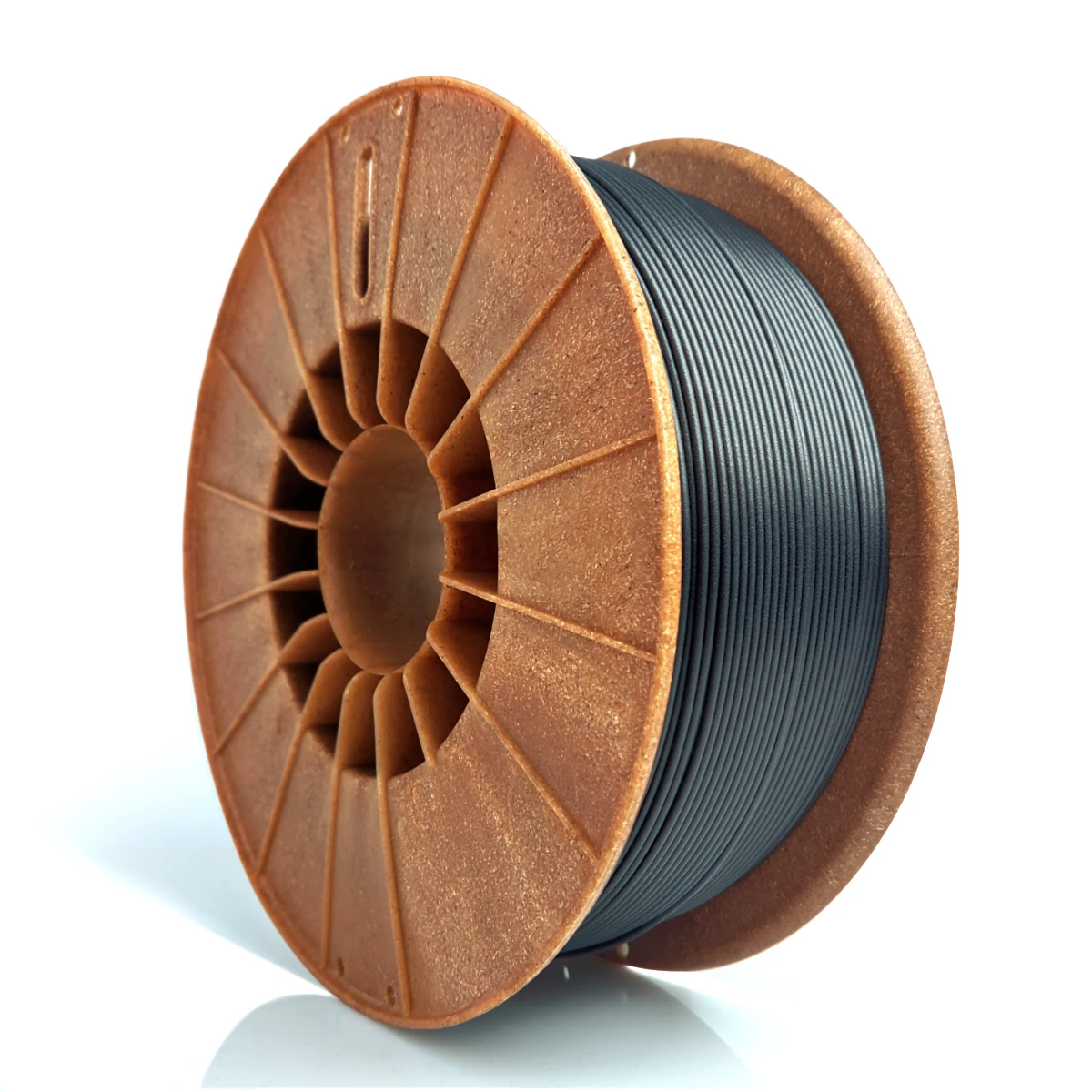

1000 g/ 2500 gColor

Color

APPLICATION

APPLICATION

- Prototypes of machine parts, gadgets, exhibition models

- Parts in electronics

- Computer parts

- Toys: building blocks, car components, educational aids

HOW TO PRINT

HOW TO PRINT

extrusion temperature: 230-270°C , table temperature: 80-110°C

Printing in a closed chamber on a heated table is recommended. If there are problems with adhesion, we recommend using an adhesion agent. Print cooling is recommended. Its power should be adapted to the capabilities of the printer and the geometry of the model being printed.

NOTE: Printing in a well-ventilated room is recommended. Do not stay in the room for long periods of time when printing with an open chamber due to the irritating smell and fumes, which may cause dizziness or headaches in sensitive people.

TECHNICAL PARAMETERS

| Diameter | 1.75 mm |

| Diameter tolerance | +/- 0,05 |

| Oval tolerance | +/- 0,02 |

| Net weight | 1000 g/ 2500 g |

| Print temperature | 230-270 °C |

| Bed temperature | 80-110 °C |

The test standards can be found in the filament technical data sheet (TDS).

PHYSICAL PARAMETERS

| Density | 1,05 g/cm3 |

| Odor | irritating |

| Tensile elongation | 2,5 % |

| Tensile strength (to break) | 44 MPa |

| Tensile modulus | 2276 MPa |

| Thermal deformation temperature | 99 |

Files to download