Project Description

PLA Plus ProSpeed(Impact) filament by ROSA3D was created for technical applications. Perfect for printing at high speed on industrial printers. While maintaining the ease of printing from PLA, it offers better mechanical and temperature resistance than PLA Starter. The impact strength of PLA Plus ProSpeed(Impact) measured by the Izod method is almost 1.5 times higher than that of standard ABS, and after crystallization - more than twice as high.

The use of PLA Plus ProSpeed(Impact) enables mechanical processing of printed elements, which is very difficult or impossible with basic PLA. The manufactured elements can be grinded, milled, drilled, turned etc. Due to noticeable reduction in shrinkage compared to basic PLA, large-size elements can be printed.

The filament is made of a biodegradable biopolymer and is an alternative to styrene-based materials (such as ABS). PLA Plus ProSpeed(Impact) provides excellent print quality, good adhesion to the heatbed, less warping and no irritating smell.

It was made of ingredients approved for contact with food. For products that come into contact with food, certification is the responsibility of the manufacturer of the final product.

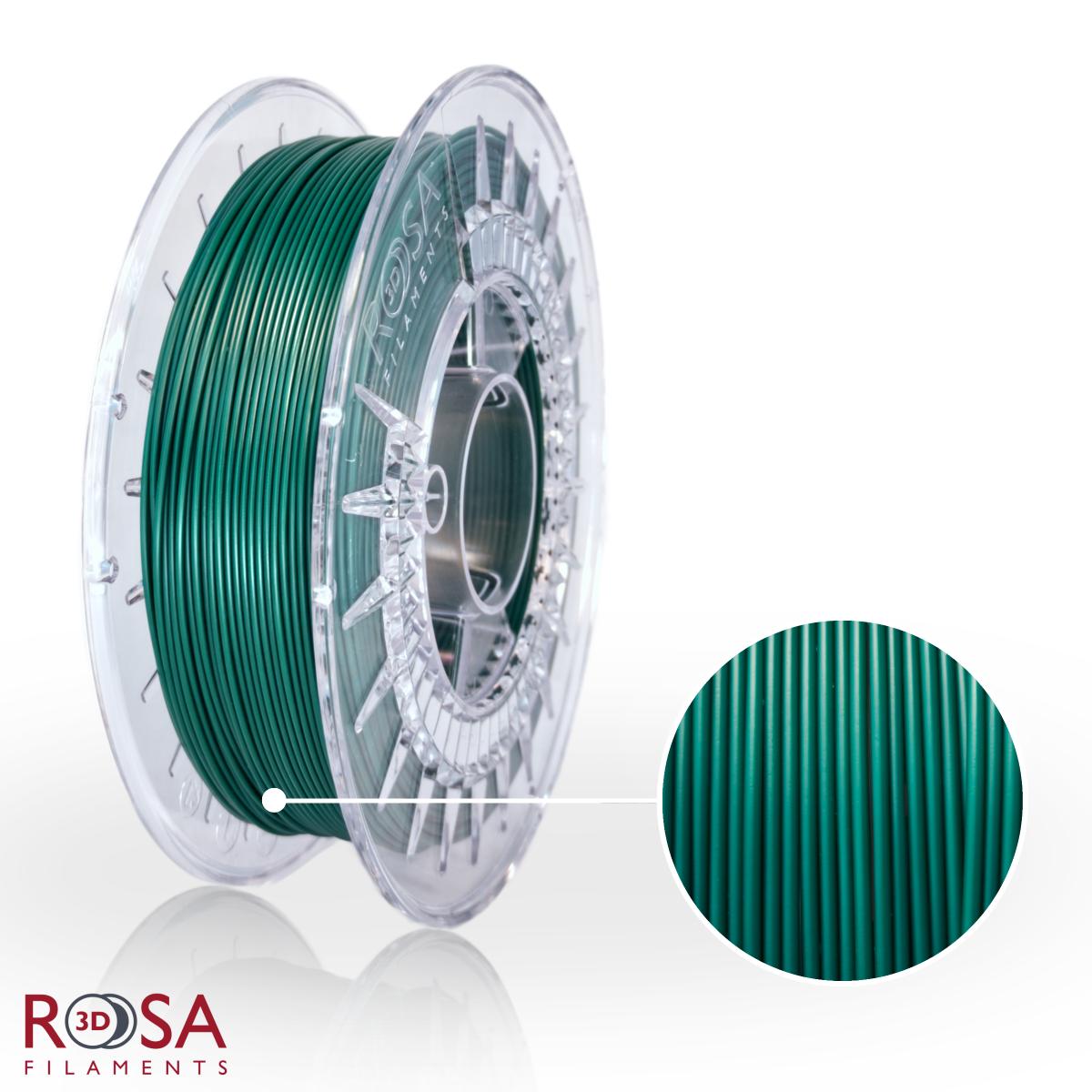

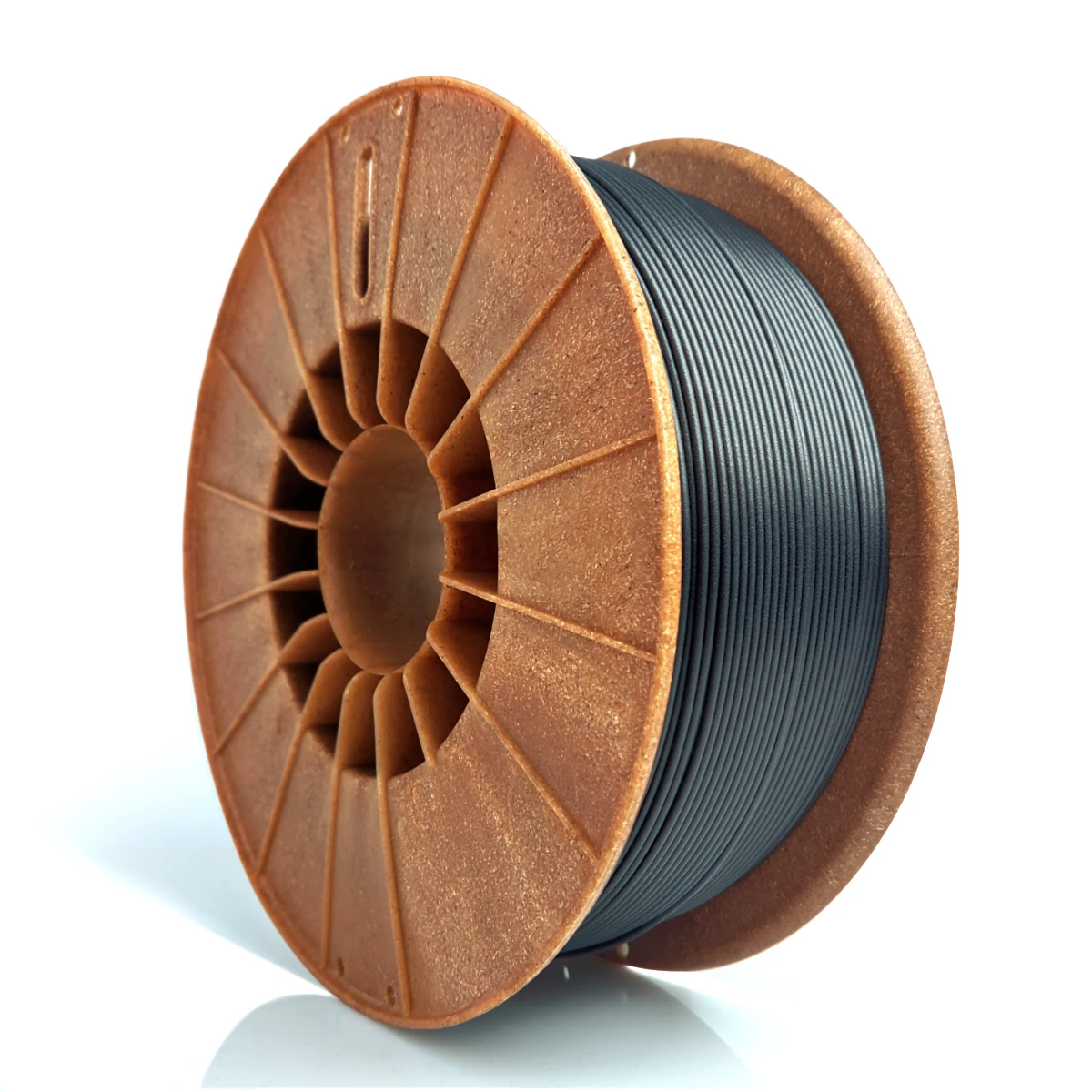

Diameter

Diameter

1.75 mmNet weight

Net weight

1000 g (vacuum packed with desiccant)Color

Color

APPLICATION

APPLICATION

Prototyping, low-volume production, machine parts, housings.

HOW TO PRINT

HOW TO PRINT

Recommended printing temperature: 190 – 230 °C.

Recommended table temperature: 50-70 °C.

For non-heated tables, it is recommended to use an adhesive agent.

TECHNICAL PARAMETERS

| Diameter | 1.75 mm |

| Diameter tolerance | +/- 0.05 mm |

| Oval tolerance | +/- 0.02 mm |

| Net weight | 1000 g (vacuum packed with desiccant) |

| Print temperature | 190-230 °C |

| Bed temperature | 50-70 °C |

The test standards can be found in the filament technical data sheet (TDS).

PHYSICAL PARAMETERS

| Density | 1.22 g/cm3 |

| Odor | Odorless |

| Tensile strength (to break) | XY axis - 40 MPa; YX axis - 32 MPa; ZX axis - 24 MPa |

| Tensile modulus | XY axis - 2865 MPa; YX axis - 2447 MPa; ZX axis - 2477 MPa |

| Thermal deformation temperature | 75-85 °C (after annealing) |

| Notched Izod impact strength | XY axis - 160 J / m; YX axis - 21 J / m; ZX axis - 109 J / m |