Project Description

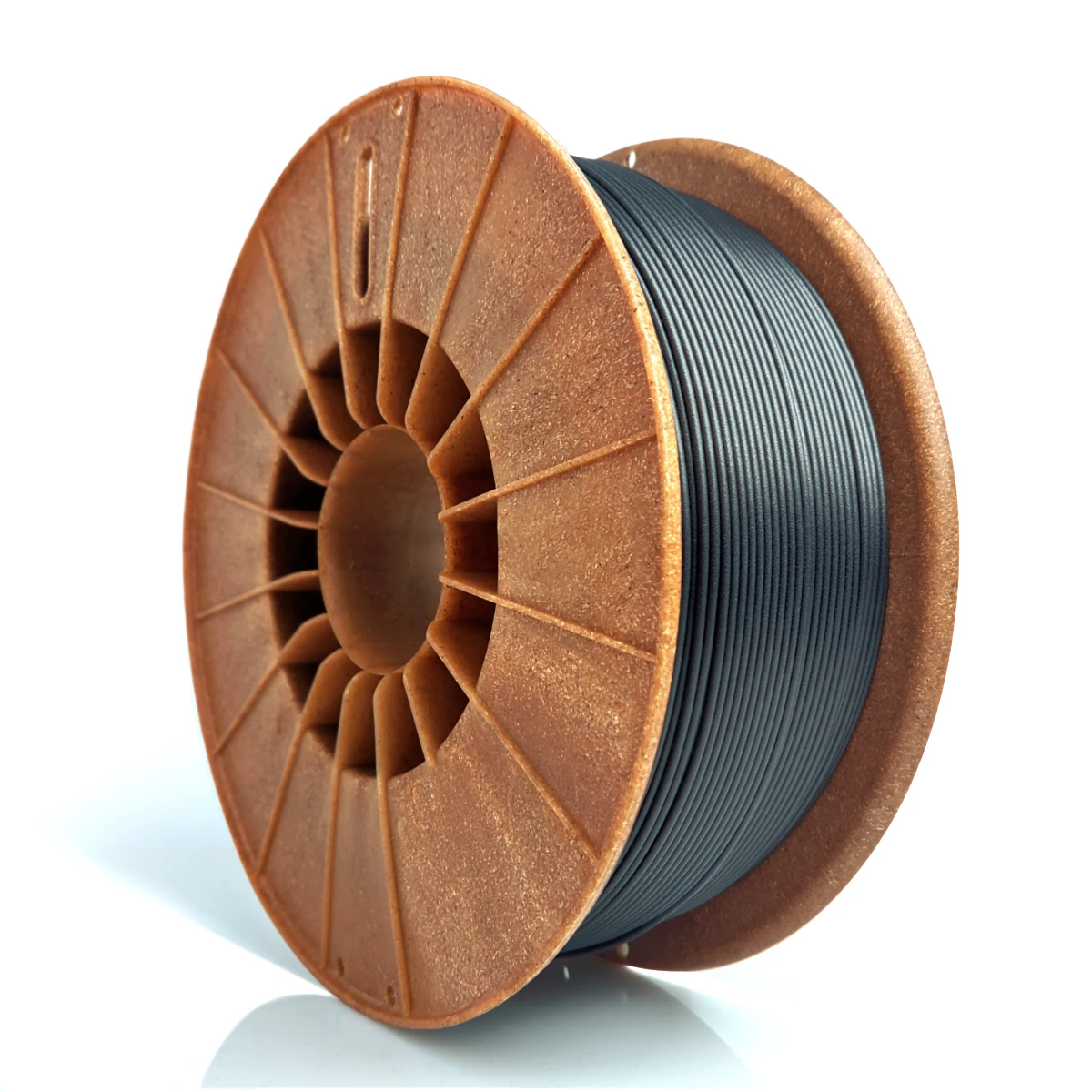

BioWOOD by Rosa3D is an easy to print FILAMENT recommended for both professionals and beginners. The material displays very minor moulding shrinkage in printing, and can be printed in an open device.

BioWOOD printouts can be subjected to mechanical treatment (such as sanding, lathing, drilling, etc.) as well as painting and lacquering, like wooden elements.

BioWOOD is manufactured from a biopolymer consisting of 100% natural and 100% renewable resources. They decompose in a natural oxygen-free environment (compost).

BioWOOD smells like natural wood. The material from which the BioWood filament is made is approved for contact with food. However, in case of products that come into contact with food, certification lies with the manufacturer of the final product.

Diameter

Diameter

1.75 mmNet weight

Net weight

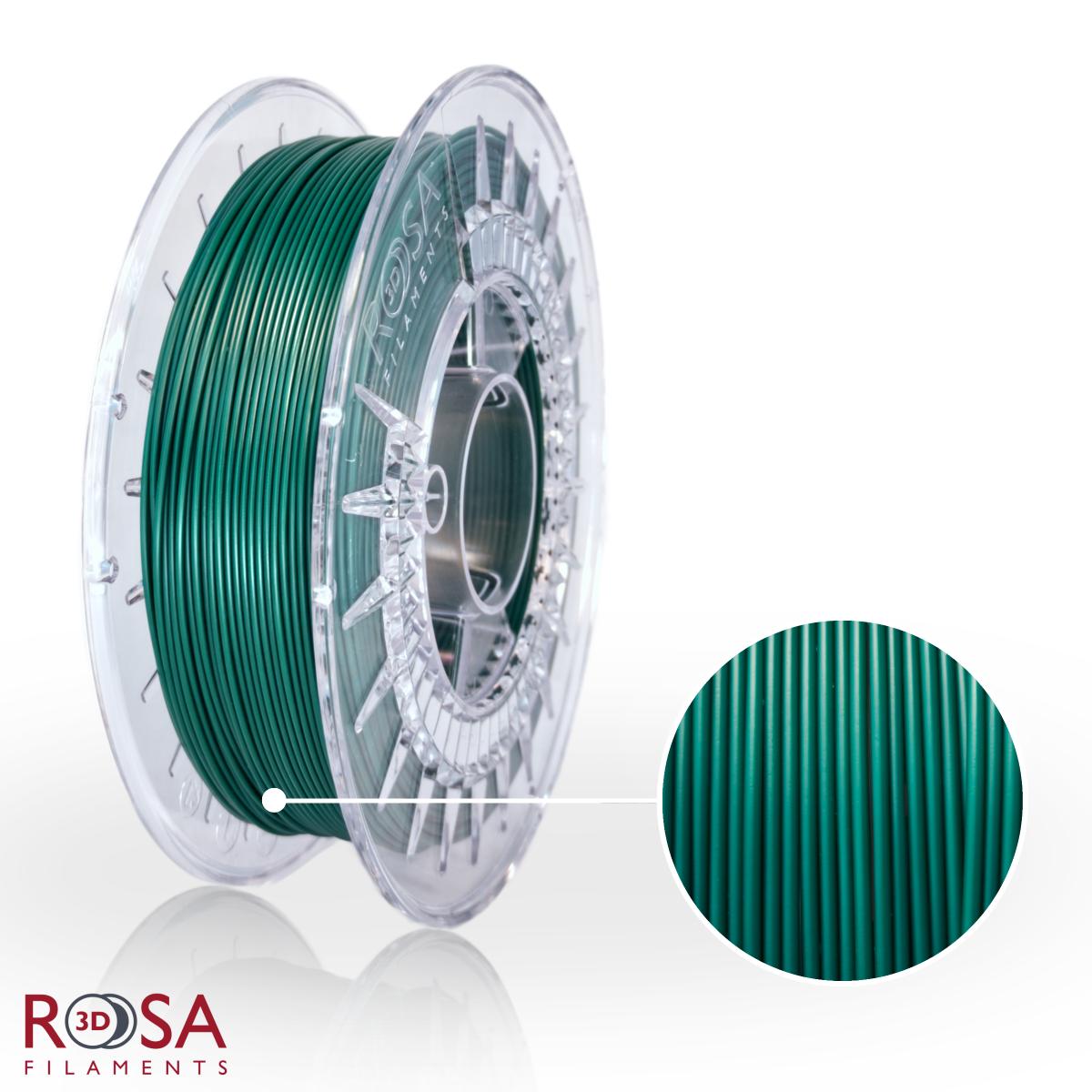

500g, 1000g (vacuum packed with desiccant)Color

Color

APPLICATION

APPLICATION

Decorative elements, dishes (bowls, plates, cups, cutlery), toys, musical instruments, furniture also renovate wooden elements.

HOW TO PRINT

HOW TO PRINT

Recommended printing temperature 170-210°C.

Recommended bed temperature: 30-50°C.

For non-heated beds, it is recommended to use an adhesive agent.

Recommended nozzle size: 0,5mm (due to the contents of wood particles).

TECHNICAL PARAMETERS

| Diameter | 1.75 mm |

| Diameter tolerance | +/- 0.05 mm |

| Oval tolerance | +/- 0.02 mm |

| Net weight | 500g, 1000g (vacuum packed with desiccant) |

| Print temperature | 170-210 °C |

| Bed temperature | 30-50 °C |

The test standards can be found in the filament technical data sheet (TDS).

PHYSICAL PARAMETERS

| Density | 1.26 g/cm3 |

| Odor | Wood |

| Tensile elongation | 3 % |

| Tensile strength (to break) | 34 MPa |

| Tensile modulus | 3200 MPa |

| Thermal deformation temperature | 55 °C |

| Vicat softening point | 50 °C |

| Charpy impact strength | 15 kJ/m2 |